How to fix crackly pots and faders on your synths, mixer and more

Bring your gear back to life

Whether it's a mixer, an effects pedal or a synthesizer, every pot (potentiometer) or fader is liable to become crackly, intermittent or send random control voltages over time as the conductive tracking inside gets coated in the dust and detritus of every day usage.

It doesn't matter how clean you keep the external facia of your equipment - dirt always finds a way in and adversely affects the variable conductive pathways of pots and faders, and no matter how many times you turn the pot or push the fader in the end, the dirt will build up to an extent where normal use is impossible.

There are a plethora of cleaning, rejuvenating and lubricating products on the market that provide simple ways to keep these important controls in good working order. Brands such as Servisol and DeOxit have a range of products for every type of moving component.

How to do it

There are main three product types needed to get the job done: an air duster (an aerosol of compressed air), a cleaner and a lubricant. Be sure to get the right product for the job as often people have used a switch cleaner (such as Servisol Super 10) on pots, which actually leaves them under-lubricated and more prone to wearing out, as well as feeling stiff and dry.

It's worth noting that occasionally a pot or fader may be so old and worn out that no amount of cleaning and lubricating will resurrect it, in which case it will need to be replaced, but that's a whole other subject.

Here's a simple guide to bringing your pot or fader back to life.

Step 1; With the unit powered off, give the pot a good number of turns (20 or more) or push the fader up and down repeatedly to loosen dirt. Use an air duster to blow out any loosened material and repeat the process once more.

Want all the hottest music and gear news, reviews, deals, features and more, direct to your inbox? Sign up here.

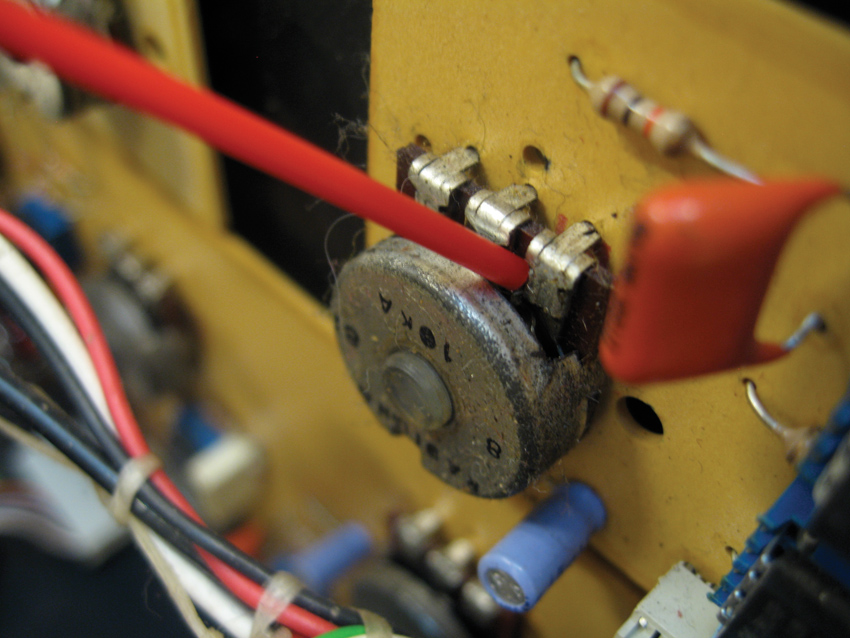

On a pot, the entry point for the air duster nozzle is where the solder tags enter the pot casing - you should be able to see the edge of the conductive track and the wiper when you turn the shaft. For a fader, push the slider to one end and insert the nozzle into the track slot at the other end pointing down, blow out the dust and repeat from the opposite end having moved the slider.

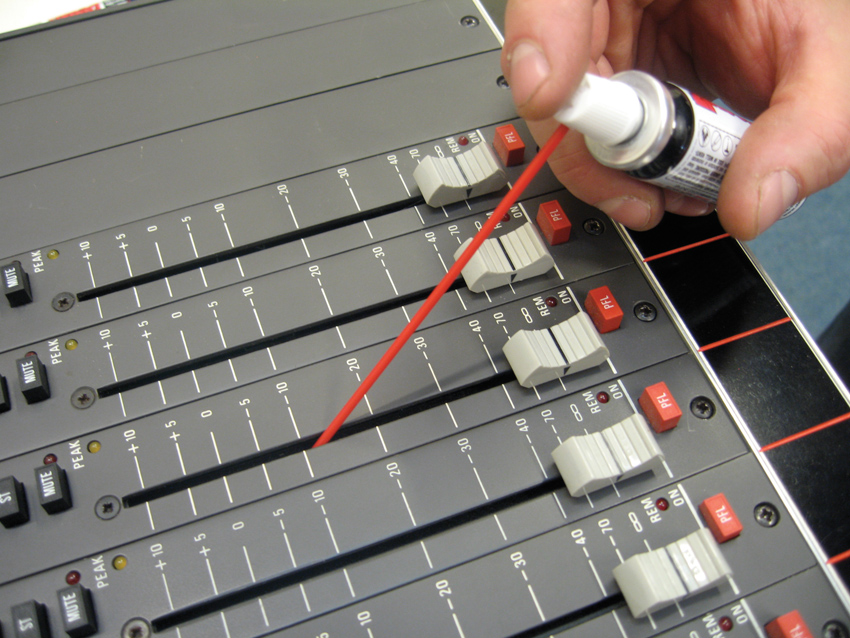

Step 2: Using the same process as with the air duster apply the contact cleaner and turn the pot or push the fader to work the compound in.

Step 3: Repeat step 2 to clean out any bound-on dirt that may have been loosened by the first application.

Step 4: Leave the cleaner to evaporate for a few minutes before powering the unit up and testing the pot/fader again.

Step 5: If the pot/fader now sounds clean, it will need lubricating, as a clean and dry pot or fader will wear out quickly and feel stiff and scratchy. The lubricant is applied in the same way as the cleaner.

The DeOxit DN5 (for pots) and F5 (FaderLube for faders) both have a lubricating action and thus seem more expensive than other products, but don't be fooled as they both excel at this task.

Future Music is the number one magazine for today's producers. Packed with technique and technology we'll help you make great new music. All-access artist interviews, in-depth gear reviews, essential production tutorials and much more. Every marvellous monthly edition features reliable reviews of the latest and greatest hardware and software technology and techniques, unparalleled advice, in-depth interviews, sensational free samples and so much more to improve the experience and outcome of your music-making.