Access All Areas: On the road with Rush

Access All Areas: On the road with Rush

Hard to believe, but Rush are celebrating their fourth decade as arena headliners, and they’re doing so in style with their biggest outing yet, the Time Machine tour. The Canadian powerhouse is also experiencing a phenomenon so rare in music that it is almost without precedence: with each passing year, their popularity grows as their relevance deepens.

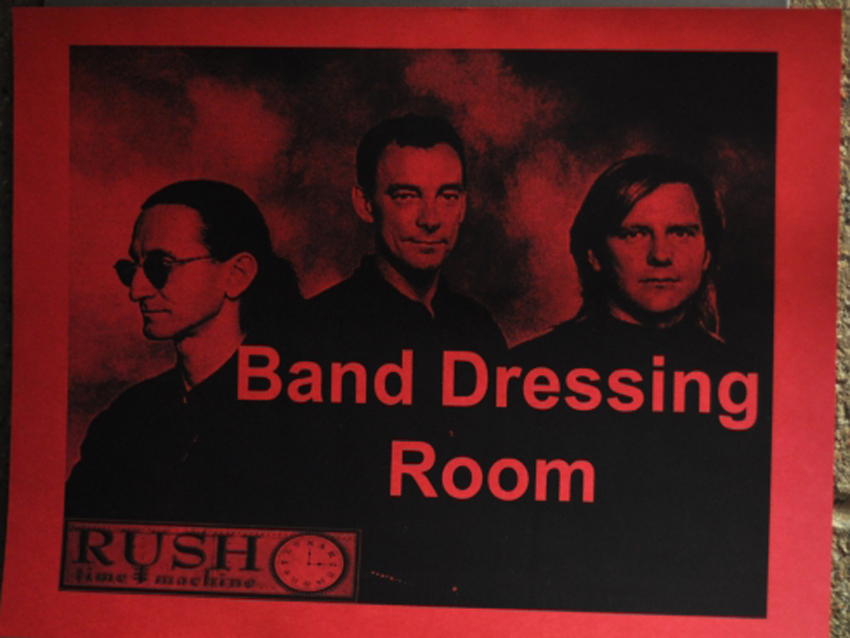

For a band whose next album, Clockwork Angels, isn’t due until sometime in 2012, the Time Machine tour is something of a victory lap. But the beloved trio (Alex Lifeson, Geddy Lee and Neil Peart – did we really have to tell you their names?) are putting some kick in their steps as they perform their 1981 classic Moving Pictures in its entirety.

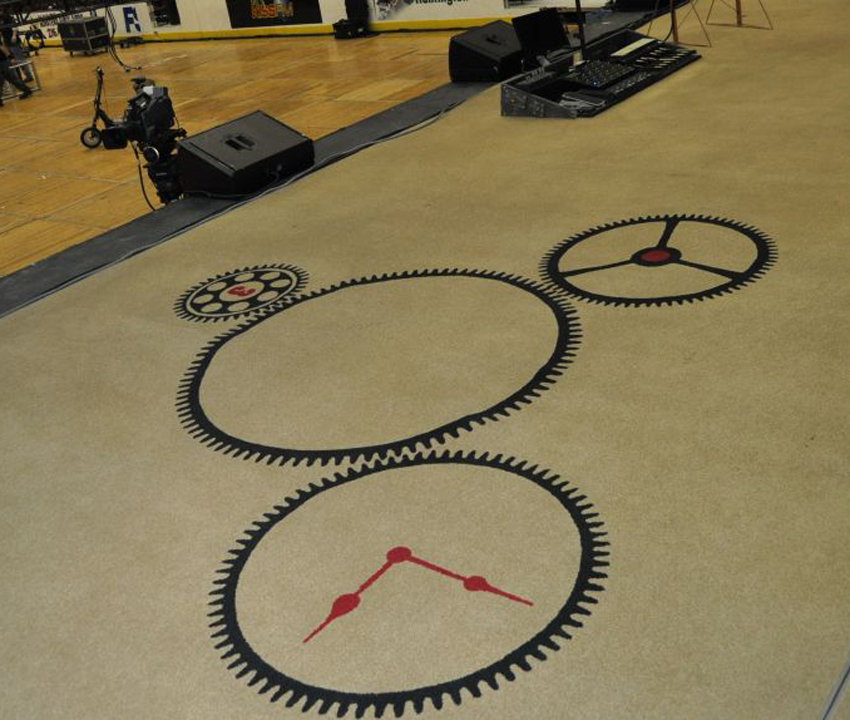

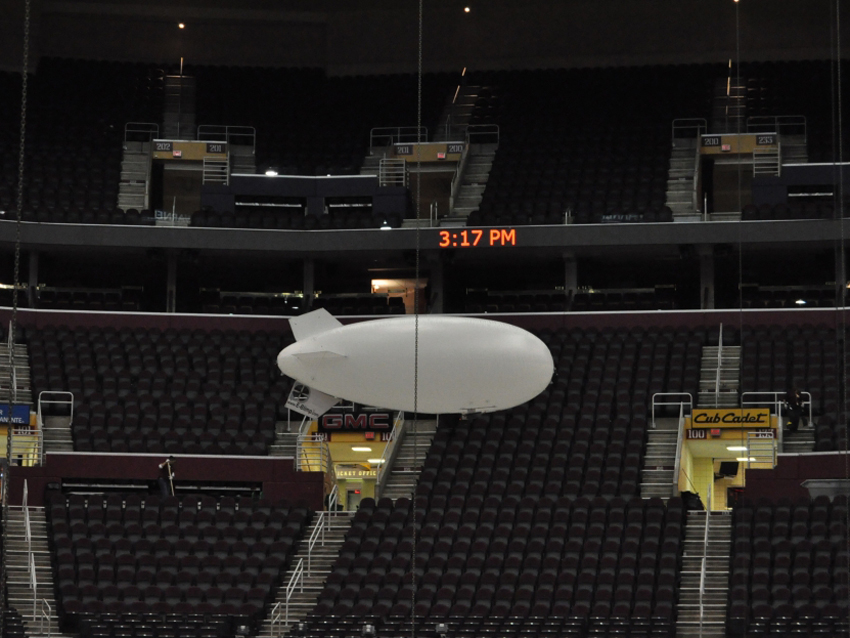

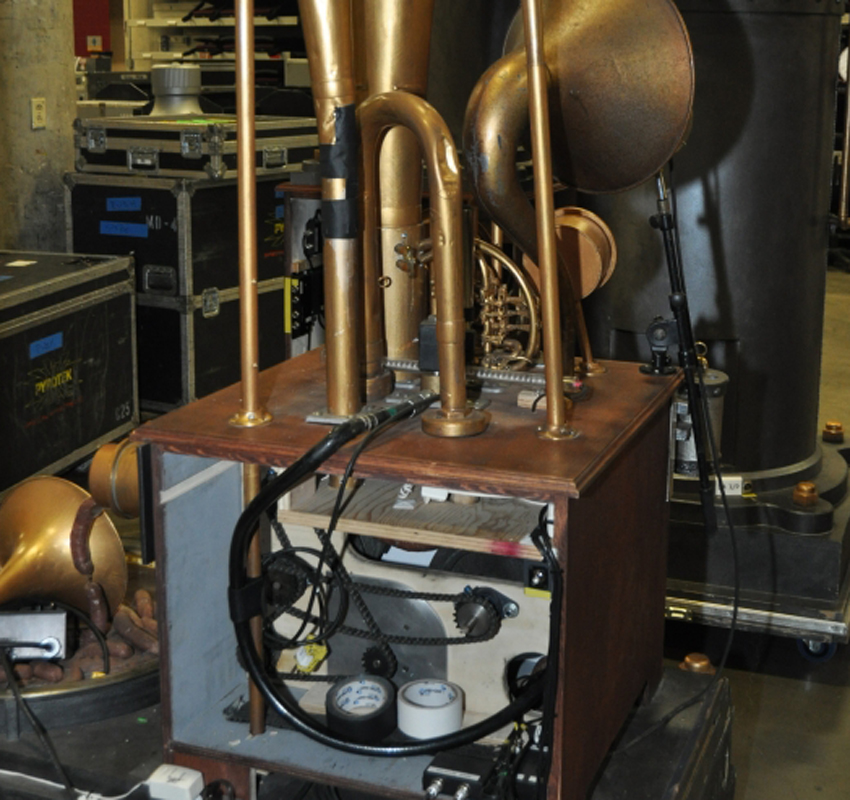

With a dazzling multimedia presentation and a brilliantly rendered steampunk motif, the Time Machine tour is a three-hour precision operation both on stage and off. But for the seasoned pros who toil behind the scenes, it’s an all-day and all-night affair as they make sure every speaker line is assembled and hung properly, each video screen is good to go and every blast of pyro goes off without a hitch.

Journalist Paul Beaulieu, who oversees an exceptionally fine blog called The Canadian Music Scene, recently got a chance to hang with Rush’s tech crew to gain an inside look at some of the fascinating (and extremely intricate) elements that go into mounting this doozy of a show. His report is now part of our exclusive new series on MusicRadar, Access All Areas.

So fire up some Rush, sit back, and go backstage…You don’t even need a laminate!

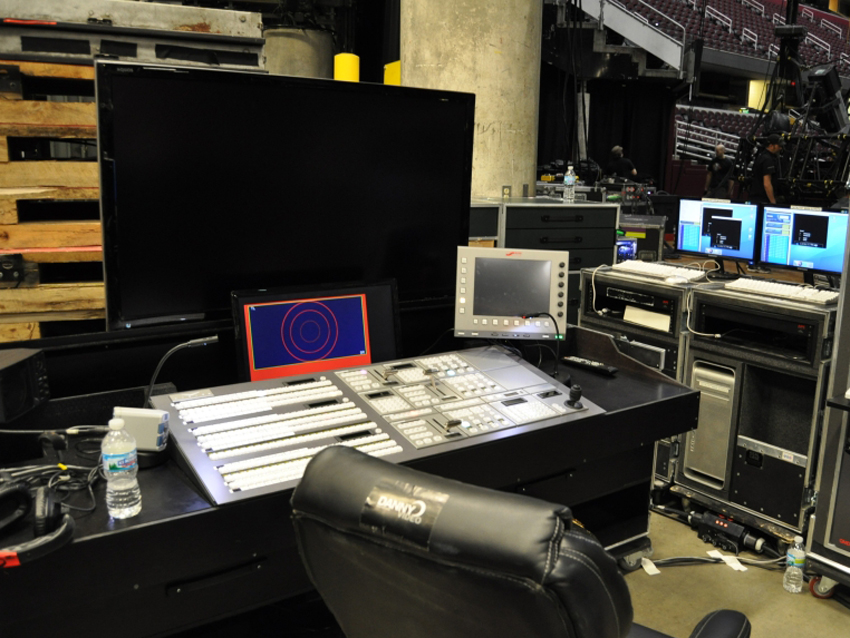

David Davidian - Video Director

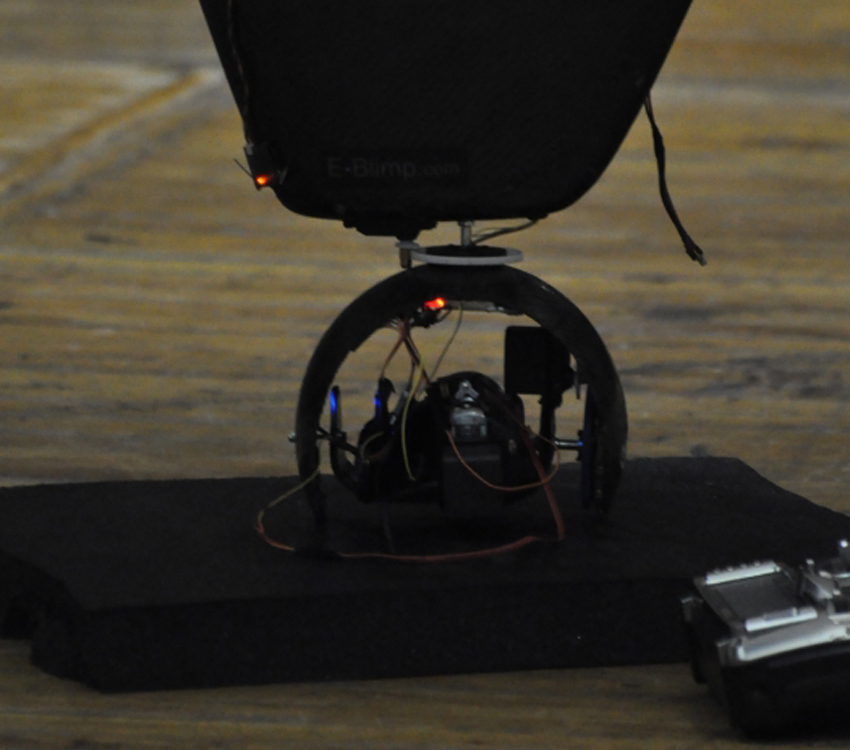

You might not know David Davidian's face, or even his name, but if you've been to Rush concert in the last nine years, you've enjoyed his work. In addition to overseeing images concertgoers see on the 40x20' WinVision 9mm LED screen, Davidian is also responsible for the video feeds into Lifeson and Lee's backlines and Peart's drum riser.

According to Davidian, his crew usually starts unloading equipment from the trucks around 10:30am. At this point, the rigging for the WinVision screen should already be in place. Next comes the job of assembling the 2x2' tiles together to form the 40x20' screen. Each of the 200 LED tiles weighs approximately 19 lbs, bringing the total weight of the screen to just under two tons.

Each tile has a 4,096 pixel resolution and consumes 400 watts of power. At 200 tiles, the total power consumption for the screen is 80,000 watts.

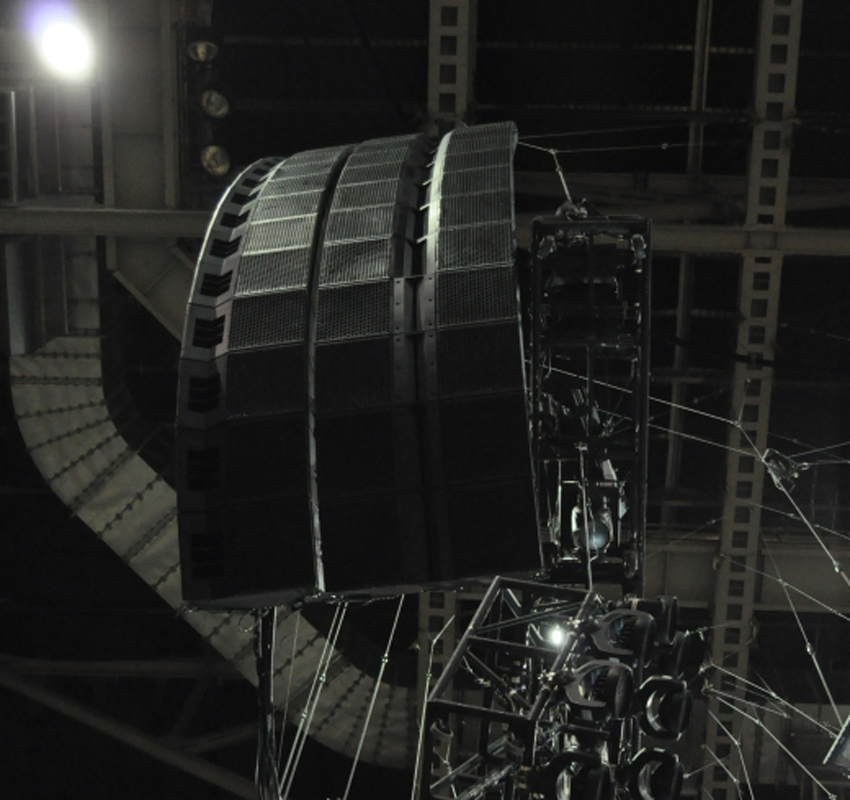

At the same time the screen is being assembled, the FOH (Front Of House) cameras that render the straight shots of the band are set up just behind the lighting control area on the floor at the back of the venue. One of the camera operators, Lindsey Haney, ensures that the wiring for the cameras located in the lighting rigging for the 'spider' are hooked up before it is hoisted into place. (Cameras in the spider capture the overhead shots, e.g. Neil Peart's drum solo).

Most of the video content on the WinVision LED screen is provided by Hippotizer's HD Green Hippo media servers. Catalyst media servers produce the video for Lifeson and Lee's backlines and for Peart's drum riser.

After the show, breakdown usually takes between one hour and 90 minutes.

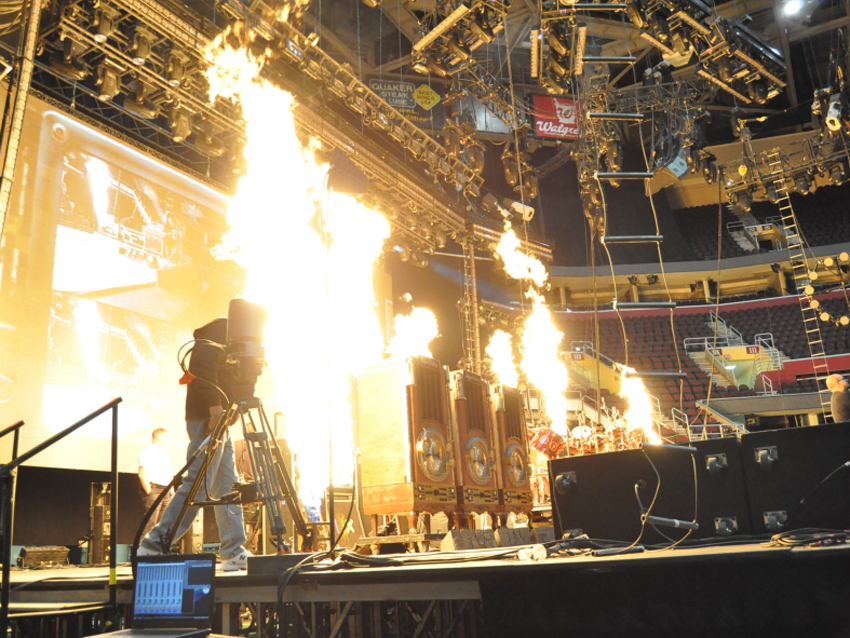

John Arrowsmith - Pyro Technician

John Arrowsmith's day starts around 9am when his gear is unloaded from the trucks and is then prepped for the show. As with any gear that needs to be on the actual stage, the schedule of its placement depends on whether the venue has a stationary or rolling stage.

According to Arrowsmith, with a stationary stage all crew members requiring access to the stage need to wait until the lighting gear, on this tour mainly the spider, has been rigged, cabled and lifted into position.

A rolling stage is out in the middle of the venue’s floor, and therefore the band members' backlines can be set up while Arrowsmith sees to the pyrotechnic devices. (Once the spider has been raised to show height, the stage can be rolled into place, and a few final setup procedures are then seen to, leaving most of the crew with much more time than normal.)

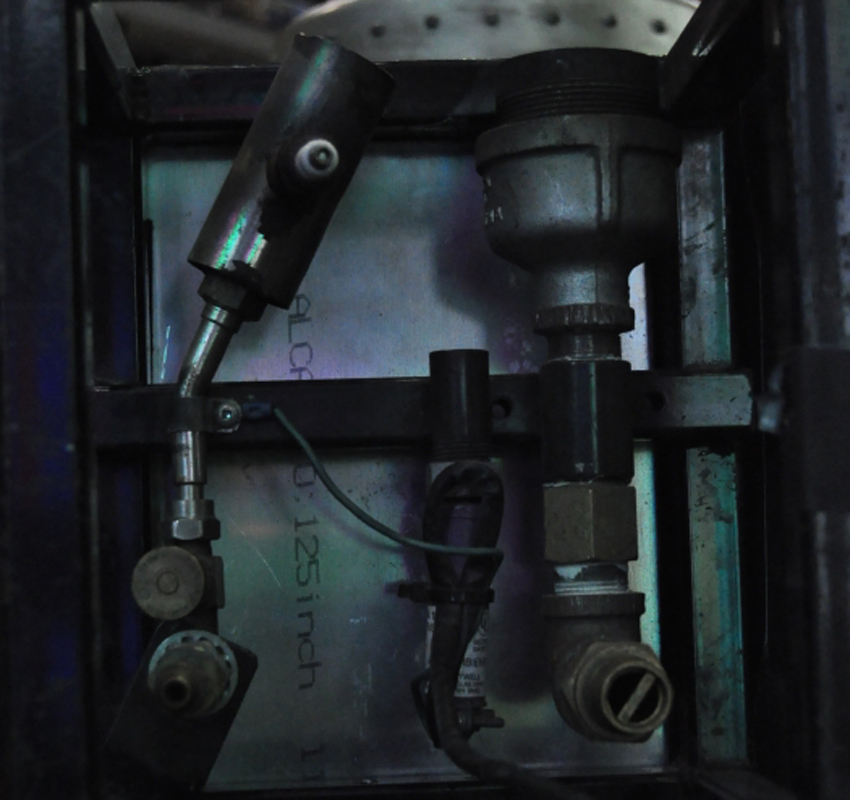

For the flames, John uses propane gas, which is fed through lighting devices (or flame throwers in tech talk) at 80 PSI (pounds per square inch) - this is the pressure required so that the fire can reach heights of 15 to 20 feet. Each flame thrower has an XLR connection that is hooked up to a board that Arrowsmith uses to ignite the pilot lights.

Arrowsmith reveals that the 'steam' discharged through the band's backlines isn't really steam, but rather it's CO2 (works better, looks cool). In addition to flames and CO2, Arrowsmith also sets off some good old-fashioned fireworks, such as the Lazy Red Comet flares for the song Caravan, and Ultra-Fast Silver Comet flares with one-second Silver Gerbs (for sparkle effect) for Far Cry.

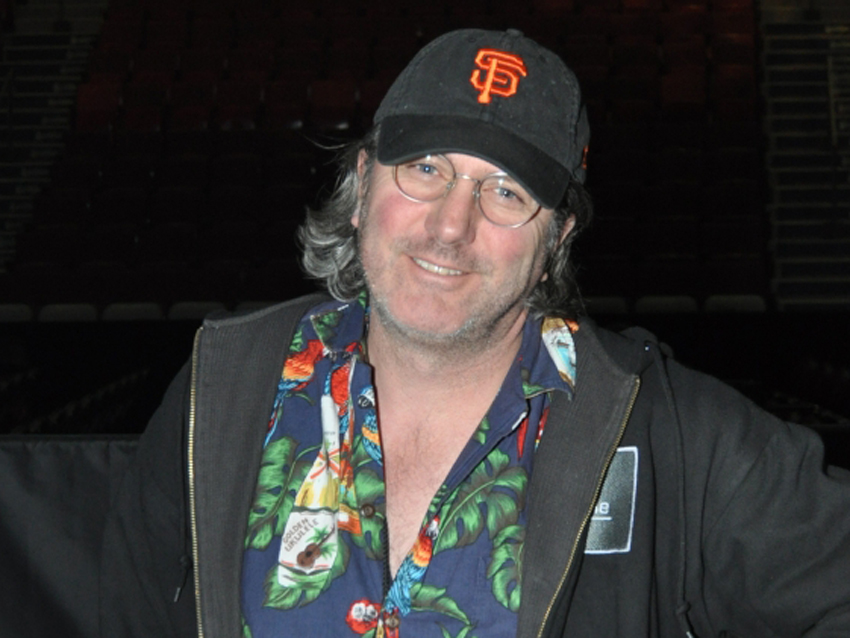

Brad Madix - Sound

Brad Madix has been a member of the Rush team since the last half of the Roll The Bones tour in 1992. He oversees the FOH sound (meaning what the concertgoers hear), while Brent Carpenter provides ear monitor mixes for the band.

Madix and Carpenter utilize Digidesign Venue D-Show Profile mixing consoles, both of which are loaded with plugins from McDSP such as Channel G, MC2000 multi-band compressor and ML4000 multi-band effects/dynamics software. During the show, Carpenter is situated at stage left (near Geddy Lee), while Madix sits at his console near the back of the auditorium.

All of the inputs are fed into Digidesign stage racks and converted to digital. A digital snake system replaces the bulky analog snakes and provides bi-directional communications for audio and control data. Digital transportation prevents ground loops between the stage and mix position.

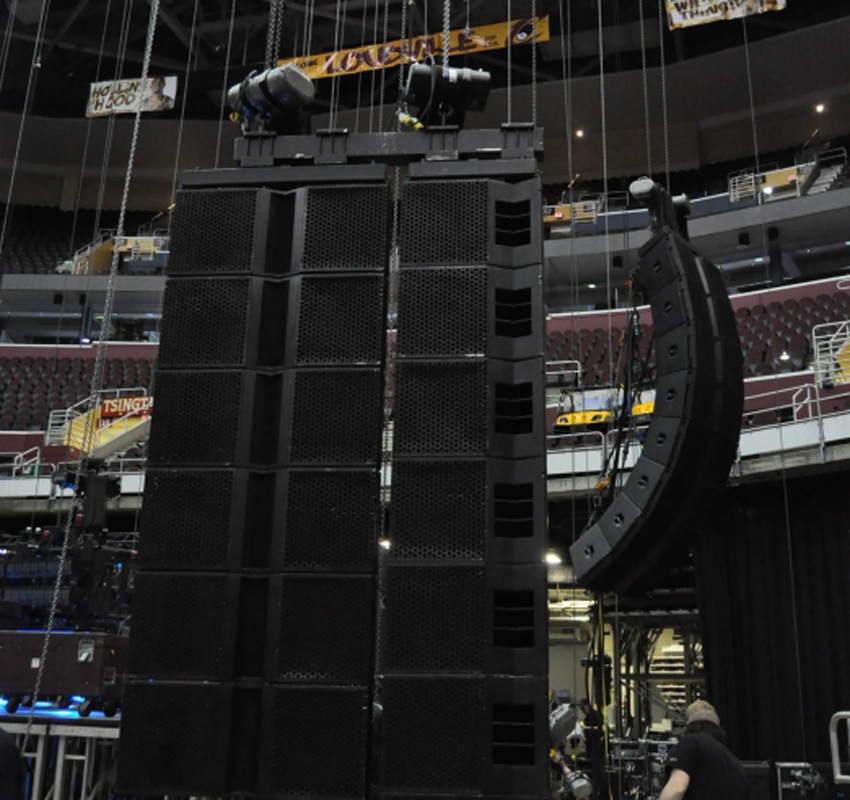

Between 8 and 8:30am, riggers begin to unload the sound gear from the trucks. The top speakers (all are manufactured by Clair Brothers) are hooked up to large clamps which in turn are attached to electric motors that will be used to lift the speakers and cables up and into position. As the speaker columns are assembled, the motors raise them slightly off the floor until they're complete and ready for positioning.